Sustainable Fibers, Reimagined from the Molecule Up

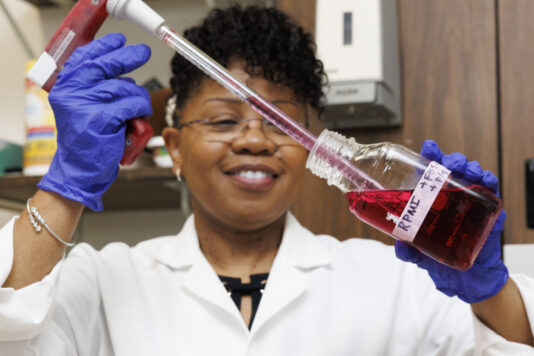

Most people never think about where fibers come from. They don’t picture the chemistry, the heat, the solvents, or the engineering behind the clothes they wear, the furnishings they lean against, or the protective gear that keeps service members safe. But during her postdoctoral associateship with the National Research Council (NRC) and at the U.S. Army Combat Capabilities Development Command (DEVCOM) Soldier Center in Natick, Massachusetts, Dr. Ericka Ford saw the unseen side of fiber manufacturing– the part most people overlook– and realized it was a matter of national significance.

At the U.S. Army Lab, she watched researchers searching for sustainable flame retardants for military uniforms. It was a subtle but defining moment. “It occurred to me that sustainability and fiber manufacturing were matters of national importance,” she recalled. What others treated as routine materials science, she saw as a high-stakes puzzle: how to make the fibers society relies on safer, cleaner, and more responsible without sacrificing performance.

That question followed her into academia. It became the foundation of her work.

In 2014, when Dr. Ford launched the Fiber Innovation Team within NC State University’s Wilson College of Textiles, she watched graduate students experiment with spinning performance fibers using lignin– a biopolymer byproduct of paper making. What began as a scientific curiosity soon evolved into something larger: a deep exploration of how to substitute or eliminate hazardous chemicals and processes across fiber manufacturing.

It was here that sustainability stopped being a backdrop and became the central force of her research. “Sustainability makes sense in cases where it reduces hazardous [materials] and costs,” she said.

For Dr. Ford, that blend of scientific creativity and practical impact was irresistible.

Her path to becoming one of the country’s most forward-thinking fiber researchers didn’t begin in a lab– it began in manufacturing plants. As a teenager, she spent her summers interning within BP Amoco Fabrics and Fibers (BPAMOCO) through the INROADS program, gaining exposure to the textile field almost before she could drive.

Those early experiences shaped her. After declaring textile engineering as her major at Georgia Tech, she found herself in project and quality control roles where she could make tangible contributions. But when she stepped into R&D, something shifted. She wanted to understand the chemistry itself– how polymers behave, how plastics influence manufacturing, and how materials could be redesigned at their source.

That curiosity led her to the University of Southern Mississippi for graduate studies in polymer science. There, she joined the Thames-Rawlins Research Group, known for pioneering environmentally friendly coatings. Their work– including American Pride Paints, which used vegetable oils instead of volatile organic compounds (VOCs) to power their performance– left a lasting imprint on her.

The group demonstrated that sustainability wasn’t just a moral choice– it could be a marketable one. Academia could partner with industry, and together, they could scale technologies that were both high-performing and cleaner for the world.

Her doctoral work at Georgia Tech, under Dr. Satish Kumar, focused on spinning high-strength, high-modulus fibers using the gel-spinning technique. But even as she mastered the chemistry, she couldn’t ignore the tradeoffs. The solvents used in gel spinning were often VOCs– flammable, hazardous, and energy-intensive.

That experience sharpened her mission.

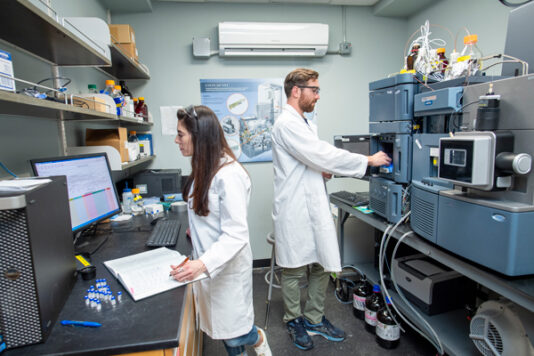

Today, as an associate professor at NC State, Dr. Ford is developing synthetic wool fibers from acrylic using a process completely free of VOCs. Instead of relying on toxic solvents, her lab is incorporating raw materials derived from nature and creating manufacturing pathways that drastically reduce environmental impact.

Her one-sentence explanation of AcrylFLOW– the process she developed– belies the magnitude of its implications:

To the outside world, it sounds simple. In reality, it represents a reimagining of how PAN– the polymer resin used to make acrylic fibers and as the precursor to carbon fiber– is formed.

Traditional PAN fibers require dissolving polymers into solutions that rely heavily on VOCs. AcrylFLOW does something fundamentally different: it melts PAN resins directly, eliminating the need for toxic solvents altogether.

This shift delivers two major advantages. The environmental benefit of no VOCs means cleaner air, safer facilities, and fewer hazardous waste streams. Plus, the energy benefit of melting PAN requires far less energy than dissolving it– especially when sugar-derived additives are used to reduce energy input.

The result is a manufacturing method that could reduce the carbon footprint of fiber production by two-thirds– a transformational number for a global industry built on synthetic materials.

And the economics follow suit. Shorter lead times for U.S. yarn and textile manufacturers.

Cleaner production without higher fiber costs. A pathway to revitalizing domestic supply chains with sustainable technology.

Dr. Ford sees the earliest impact in architectural furnishings– public spaces where durability and safety matter most. From seating to wall systems to commercial interiors, the materials that surround people every day could soon be made with fibers that preserve human and environmental health without compromising performance.

“Performance fabrics and fibers were created to enhance the quality of life,” she said. “They should do so without causing unforeseen harm.”

Before NCInnovation funding, Dr. Ford’s lab had proven the process at the bench scale. What they lacked was the ability to demonstrate fiber spinning in a commercial setting– an essential step for industry adoption.

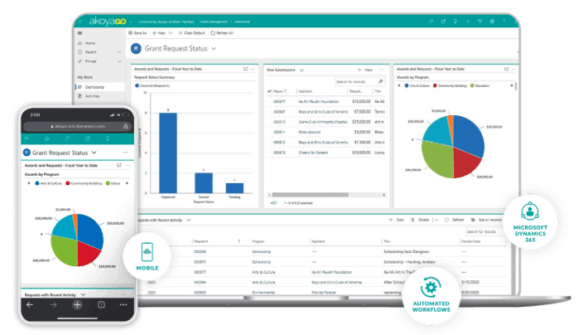

NCInnovation is now filling that gap.

By funding the scale-up, NCInnovation is enabling a complete supply chain– from raw materials to customer validation– to be demonstrated within two years. It’s a rare opportunity for an academic innovation to reach the level of commercial readiness required for industry confidence.

Success, in her mind, is clear and measurable: customer validation and product orders.

While students are not hands-on in the current project– commercial partners and research technicians at The Nonwovens Institute (NWI), headquartered on NC State’s Centennial Campus, are managing resin scaling and fiber spinning– the impact on her lab is already evident. Two students who helped patent this technology are now employed in industry and at a national laboratory.

It is the kind of trajectory Dr. Ford sees as part of her purpose: educating the next generation of scientists who can build technologies that respect both performance and the planet.

Dr. Ericka Ford’s work marks a quiet but significant shift in the textiles field. What began with curiosity in high-school internships and crystallized in military research has become one of the country’s most promising pathways toward clean, scalable, high-performance fibers.

And with NCInnovation’s support, her work is no longer just a lab-scale breakthrough.

It’s becoming a manufacturable future– one where performance materials serve people, protect the environment, and strengthen the nation’s industrial resilience.

This is fiber manufacturing reimagined from the molecule up. And its impact could be felt for decades to come.