ECU Researchers Build a Low-Cost Wind Tunnel to Strengthen Mosquito Control and Protect Public Health

Each summer, mosquitoes do more than buzz and bite—they spread disease. West Nile, Eastern equine, and La Crosse encephalitis viruses are already present in North Carolina, and after hurricanes and flooding, mosquito populations surge, posing serious public health risks. Yet for many counties, routinely testing the efficacy of their mosquito control treatments is out of reach.

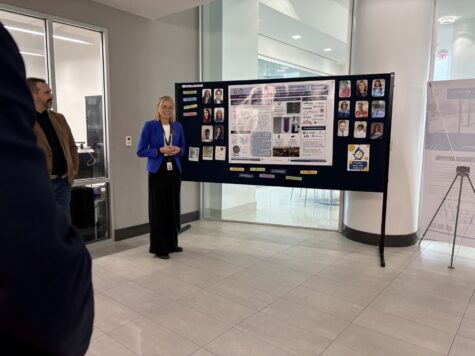

That challenge inspired Dr. Stephanie Richards, professor of environmental health at East Carolina University’s College of Health and Human Performance, and Dr. Sinan Sousan, associate professor in the Department of Public Health at Brody School of Medicine, to develop a new way to measure what works—without the expense and logistical issues of large-scale field trials. Initial funding by sources such as I-Corps@ECU, NC Biotechnology Center, and NC Department of Health and Human Services helped the pair design a compact wind tunnel prototype that simulates outdoor spraying conditions in the lab, allowing health departments and pesticide companies to test insecticide performance safely, quickly, and affordably.

Supported by NCInnovation—which funds late-stage applied-research and commercialization milestones—the investigators will finalize the wind-tunnel design, complete validation testing, and accelerate plans to launch a contract research organization.

Traditional field trials for mosquito control are expensive, weather-dependent, and often impractical. “If it’s rainy, too windy, not windy enough, or too hot, you can’t do the tests,” Richards explains. “You’re bringing in personnel, using truck-mounted ultra-low volume application equipment, setting up tripods and cages, waiting until dusk for temperature inversion—and if conditions aren’t right, you have to start all over.”

Those trials can cost tens of thousands of dollars and require extensive coordination. Despite the dedication of mosquito control operators, many counties simply do not have the resources to conduct routine testing, which can make it difficult to determine whether current pesticides remain fully effective.

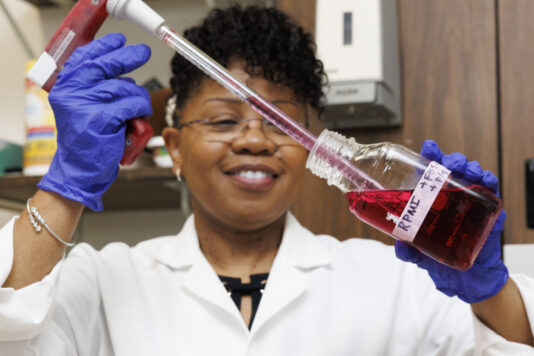

“We want to know what works, use what is needed for targeted control as part of an integrated mosquito management program, and protect both people and the environment,” says Richards.

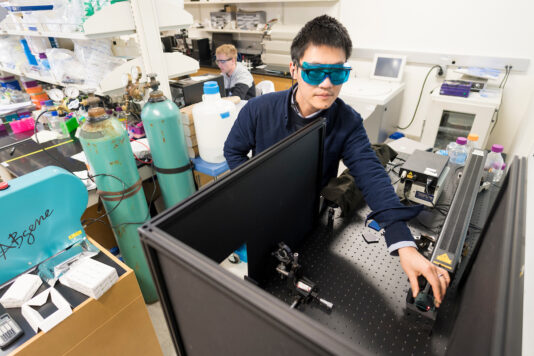

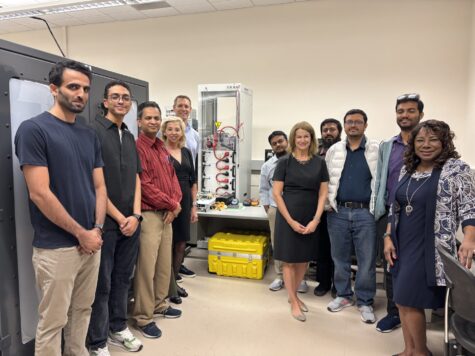

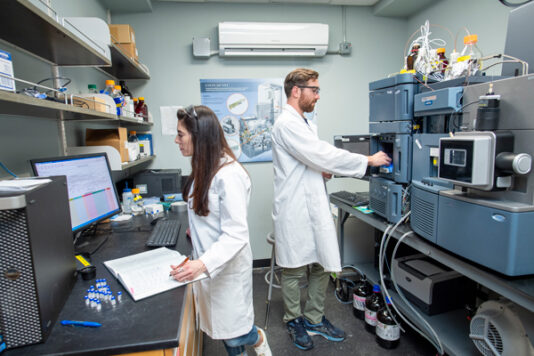

Inside ECU’s lab, the team’s bench-top wind tunnel simulates real-world spray conditions using a controlled airflow system that aerosolizes a precise amount of formulated insecticide product, exposing mosquitoes for just ten seconds before they’re transferred to an incubator for mortality monitoring.

If 98 percent or more die, the product is effective. Between 90 and 97 percent, the mosquito population is developing resistance. Below 90 percent, the population is considered resistant—following CDC guidelines.

Dr. Sousan, an aerosol scientist and engineer, led the wind tunnel design, building and calibrating the prototype to mirror real-world conditions as closely as possible. His expertise in airflow dynamics and droplet behavior helped ensure that the system accurately reproduces what happens during actual mosquito control treatments.

“Our goal was to bring field-quality precision into a controlled lab space,” Sousan says. “By fine-tuning airflow, droplet size, and humidity, we can simulate what happens outdoors—without the expense or uncertainty of field conditions.”

Support from NCInnovation has been pivotal in bringing the concept from prototype to commercialization. The grant allowed Richards and Sousan to purchase essential lab equipment—including an incubator—and to partner with state mosquito control programs for testing and feedback.

“NCInnovation funding opened doors for us,” Richards says. “It’s helping us refine the model, improve efficiency, and validate the technology against field data. It’s also helping us explore business models and customer discovery.”

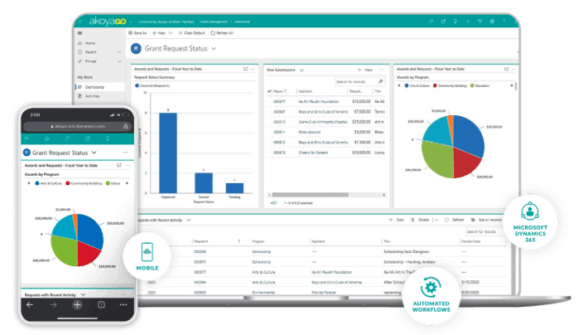

For small or rural counties, this new system could be transformative. Instead of relying on expensive and weather-dependent field trials or lack thereof, health departments can use the wind tunnel insecticide testing service as a screening tool to determine whether a pesticide is worth testing in the field—or whether resistance makes it ineffective.

That efficiency translates to huge savings and faster responses during outbreak seasons. “After hurricanes, when mosquito populations surge, this kind of rapid testing could help officials be more informed and act faster,” Richards says.

The platform’s commercialization potential also extends beyond county use. With interest from local and state health departments, private industry, and the potential for usage by federal agencies such as the Department of Defense, the team envisions a future where their compact system supports mosquito-control programs nationwide—and beyond.

“We already have relationships with mosquito control teams in NC and across the US,” Richards explains. “The idea is to make testing accessible, accurate, and affordable. It’s about helping communities protect the public using targeted effective control.”

Richards and Sousan are continuing to refine the prototype, validate it against additional field data, and build the partnerships needed to move it towards commercialization as a CRO. A full-time lab manager is in the process of being hired through NCInnovation funding, and plans are underway to train additional technicians and expand the facility to house multiple testing units.

“Creating jobs in eastern North Carolina and assisting the mosquito control community is part of our mission,” Richards and Sousan say. “We live in these communities. We want to protect the public and our environment while helping others do the same.”